Sugar

Background to the schools Wikipedia

SOS Children made this Wikipedia selection alongside other schools resources. SOS Child sponsorship is cool!

| Nutritional value per 100 g (3.5 oz) | |

|---|---|

| Energy | 1,619 kJ (387 kcal) |

| Carbohydrates | 99.98 g |

| - Sugars | 99.91 g |

| - Dietary fibre | 0 g |

| Fat | 0 g |

| Protein | 0 g |

| Water | 0.03 g |

| Riboflavin (vit. B2) | 0.019 mg (2%) |

| Calcium | 1 mg (0%) |

| Iron | 0.01 mg (0%) |

| Potassium | 2 mg (0%) |

| Percentages are relative to US recommendations for adults. Source: USDA Nutrient Database |

|

| Nutritional value per 100 g (3.5 oz) | |

|---|---|

| Energy | 1,576 kJ (377 kcal) |

| Carbohydrates | 97.33 g |

| - Sugars | 96.21 g |

| - Dietary fibre | 0 g |

| Fat | 0 g |

| Protein | 0 g |

| Water | 1.77 g |

| Thiamine (vit. B1) | 0.008 mg (1%) |

| Riboflavin (vit. B2) | 0.007 mg (1%) |

| Niacin (vit. B3) | 0.082 mg (1%) |

| Vitamin B6 | 0.026 mg (2%) |

| Folate (vit. B9) | 1 μg (0%) |

| Calcium | 85 mg (9%) |

| Iron | 1.91 mg (15%) |

| Magnesium | 29 mg (8%) |

| Phosphorus | 22 mg (3%) |

| Potassium | 346 mg (7%) |

| Sodium | 39 mg (3%) |

| Zinc | 0.18 mg (2%) |

| Percentages are relative to US recommendations for adults. Source: USDA Nutrient Database |

|

Sugar is a class of edible crystalline substances including sucrose, lactose, and fructose. Common table sugar (sucrose) is made from sugar beets or sugar cane. Human taste buds interpret its flavor as sweet. Sugar as a basic food carbohydrate primarily comes from sugar cane and from sugar beet, but also appears in fruit, honey, sorghum, sugar maple (in maple syrup), and in many other sources. It forms the main ingredient in much candy. "Excessive" consumption of sugar has been associated with increased incidences of type 2 diabetes, obesity and tooth decay.

Terminology

Popular

In non-scientific use, the term sugar refers to sucrose (also called "table sugar" or "saccharose") — a white crystalline solid disaccharide. In this informal sense, the word "sugar" principally refers to crystalline sugars.

Humans most commonly use sucrose as their sugar of choice for altering the flavor and properties (such as mouthfeel, preservation, and texture) of beverages and food. Commercially produced table sugar comes either from sugar cane or from sugar beet. Manufacturing and preparing food may involve other sugars, including palm sugar and fructose, generally obtained from corn (maize) or from fruit.

Sugar may dissolve in water to form a syrup. A great many foods exist which principally contain dissolved sugar. Generically known as "syrups", they may also have other more specific names such as "honey" or " molasses".

Scientific

Scientifically, sugar refers to any monosaccharide or disaccharide. Monosaccharides (also called "simple sugars"), such as glucose, store chemical energy which biological cells convert to other types of energy.

In a list of ingredients, any word that ends with " -ose" (such as "glucose", "dextrose", "fructose", etc.) will likely denote a sugar. Sometimes such words may also refer to any types of carbohydrates soluble in water.

Glucose (a type of sugar found in human blood plasma) has the molecular formula C6 H12 O6.

Culinary/nutritional

In culinary terms, the foodstuff known as sugar delivers a primary taste sensation of sweetness. Apart from the many forms of sugar and of sugar-containing foodstuffs, alternative non-sugar-based sweeteners exist, and these particularly attract interest from people who have problems with their blood sugar level (such as diabetics) and people who wish to limit their calorie-intake while still enjoying sweet foods. Both natural and synthetic substitutes exist with no significant carbohydrate (and thus low-calorie) content: for instance stevia (an herb), and saccharin (produced from naturally occurring but not necessarily naturally edible substances by inducing appropriate chemical reactions).

History of sugar

Originally, people chewed the cane raw to extract its sweetness. Indians discovered how to crystallize sugar during the Gupta dynasty, around 350 AD. John F. Robyt (1998) locates the two most probable origins of sugar cultivation as South Pacific or the North East India, which provide evidence of sugarcane cultivation as early as 10,000 BC and 6,000 BC respectively. Further archaeological evidence associates sugar with the Indus valley.

During the Muslim Agricultural Revolution, Arab entrepreneurs adopted the techniques of sugar production from India and then refined and transformed them into a large-scale industry. Arabs set up the first large scale sugar mills, refineries, factories and plantations.

The 1390s saw the development of a better press, which doubled the juice obtained from the cane. This permitted economic expansion of sugar plantations to Andalucia and to the Algarve. The 1420s saw sugar production extended to the Canary Islands, Madeira and the Azores.

The Portuguese took sugar to Brazil. Hans Staden, published in 1555, writes that by 1540 Santa Catarina Island had 800 sugar mills and that the north coast of Brazil, Demarara and Surinam had another 2000. Approximately 3000 small mills built before 1550 in the New World created an unprecedented demand for cast iron gears, levers, axles and other implements. Specialist trades in mold-making and iron-casting developed in Europe due to the expansion of sugar production. Sugar mill construction developed technological skills needed for a nascent industrial revolution in the early 17th century.

After 1625 the Dutch carried sugarcane from South America to the Caribbean islands — where it became grown from Barbados to the Virgin Islands. The years 1625 to 1750 saw sugar become worth its weight in gold. With the European colonization of the Americas, the Caribbean became the world's largest source of sugar. These islands could supply sugarcane using slave labor and produce sugar at prices vastly lower than those of cane sugar imported from the East.

During the eighteenth century, sugar became enormously popular and the sugar market went through a series of booms. As Europeans established sugar plantations on the larger Caribbean islands, prices fell, especially in Britain. By the eighteenth century all levels of society had become common consumers of the former luxury product. At first most sugar in Britain went into tea, but later confectionery and chocolates became extremely popular. Suppliers commonly sold sugar in solid cones and consumers required a sugar nip, a pliers-like tool, to break off pieces.

Beginning in the late 18th century, the production of sugar became increasingly mechanized. The steam engine first powered a sugar mill in Jamaica in 1768, and soon after, steam replaced direct firing as the source of process heat. Today, a large beet refinery producing around 1,500 tonnes of sugar a day needs a permanent workforce of about 150 for 24-hour production.

Sugar is produced in manufactures that bring in the beet, which consists of sugar. First they start out with extraction of the pulp, the pulp is given to animals as food and the remainder is used in the production of sugar. Sugar main from a sugar beet is equivalent to sugar cane. The sugar we find in our local supermarkets is all produced the exact same way as it was in the olden days. Sugar is used in a wide-variety of products such as baking sugar, candy, art, and many other uses. Sugar is also found in alcoholic beverages and in the soap that we wash ourselves with everyday.

Etymology

In the case of sugar, the etymology reflects the spread of the commodity. The English word "sugar" originates from the Arabic and Persian word shakar, itself derived from Sanskrit Sharkara. It came to English by way of French, Spanish and/or Italian, which derived their word for sugar from the Arabic and Persian shakar (whence the Portuguese word açúcar, the Spanish word azúcar, the Italian word zucchero, the Old French word zuchre and the contemporary French word sucre). (Compare the OED.) The Greek word for "sugar", zahari, means "pebble". Note that the English word jaggery (meaning "coarse brown Indian sugar") has similar ultimate etymological origins (presumably in Sanskrit).

As a food

Originally a luxury, sugar eventually became sufficiently cheap and common to influence standard cuisine. Britain and the Caribbean islands have cuisines where the use of sugar became particularly prominent.

Sugar forms a major element in confectionery and in desserts. Cooks use it as a food preservative as well as for sweetening.

Human health

Some commentators have suggested links between processed sugar consumption and health hazards, including obesity and tooth decay. John Yudkin showed that the consumption of sugar and refined sweeteners is closely associated with coronary heart disease. It is also considered as a source of endogenous glycation processes.

Tooth decay

Tooth decay has arguably become the most prominent health hazard associated with the consumption of sugar. Oral bacteria such as Streptococcus mutans live in dental plaque and metabolize sugars into lactic acid. High concentrations of acid may result on the surface of a tooth, leading to tooth demineralization.

The American Dental Association sees tooth decay as caused "mostly" by starchy foods like breadsticks, cereals and potato chips that linger on teeth and prolong acid production, not by simple sugars that dissolve rapidly in the mouth.

Diabetes

Diabetes, a disease that causes the body to metabolize sugar poorly, occurs when either:

- the body attacks the cells producing insulin, the chemical that allows the metabolizing of sugar in the body's cells (Type 1 diabetes)

- the body's cells ignore insulin (Type 2 diabetes)

When glucose builds up in the bloodstream, it can cause two problems:

- in the short term, cells become starved for energy because they do not have access to the glucose

- in the long term, frequent glucose build-up increases the acidity of the blood, damaging many of the body's organs, including the eyes, kidneys, nerves and/or heart

Authorities advise diabetics to avoid sugar-rich foods to prevent adverse reactions.

Obesity

In the United States of America, a scientific/health debate has started over the causes of a steep rise in obesity in the general population — and one view posits increased consumption of carbohydrates in recent decades as a major factor.

Obesity can result from a number of factors including:

- an increased intake of energy-dense foods — high in fat and sugars but low in vitamins, minerals and other micronutrients (see United Nations advice below); and

- decreased physical activity.

The National Health and Nutrition Examination Survey I and Continuous indicates that the population in the United States has increased its proportion of energy consumption from carbohydrates and decreased its proportion from total fat while obesity has increased. This implies, along with the United Nations report cited below, that obesity may correlate better with sugar consumption than with fat consumption, and that reducing fat consumption while increasing sugar consumption actually increases the level of obesity. The following table summarizes this study (based on the proportion of energy intake from different food sources for US Adults 20-74 years old, as carried out by the U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Centre for Health Statistics, Hyattsville, MD):

| Year | Sex | Carbohydrate | Fat | Protein | Obesity |

|---|---|---|---|---|---|

| 1971 | Male | 42.4% | 36.9% | 16.5% | 12.1% |

| 1971 | Female | 45.4% | 36.1% | 16.9% | 16.6% |

| 2000 | Male | 49.0% | 32.8% | 15.5% | 27.7% |

| 2000 | Female | 51.6% | 32.8% | 15.1% | 34.0% |

Another study published in 2002 and conducted by the National Academy of Sciences over a 3-year period concluded: “There is no clear and consistent association between increased intakes of added sugars and BMI.” (BMI or "Body mass index" measures body-weight and height.)

Gout

Researchers have implicated sugary drinks high in fructose in a surge in cases of the painful joint disease gout.

Cancer

A link between sugar and cancer has been conjectured for some time but this remains a controversial topic. Some recent studies lend support to this theory. However no major medical or nutritional organization currently recommends reducing sugar consumption to prevent cancer.

United Nations nutritional advice

In 2003, four United Nations agencies, (including the World Health Organization (WHO) and the Food and Agriculture Organization (FAO)) commissioned a report compiled by a panel of 30 international experts. The panel stated that the total of free sugars (all monosaccharides and disaccharides added to foods by manufacturers, cooks or consumers, plus sugars naturally present in honey, syrups and fruit juices) should not account for more than 10% of the energy intake of a healthy diet, while carbohydrates in total should represent between 55% and 75% of the energy intake.

Debate on extrinsic sugar

Argument continues as to the value of extrinsic sugar (sugar added to food) compared to that of intrinsic sugar (naturally present in food). Adding sugar to food particularly enhances taste, but does increase the total number of calories, among other negative effects on health and physiology.

In the United States of America, sugar has become increasingly evident in food products, as more food manufacturers add sugar or high fructose corn syrup to a wide variety of consumables. Candy bars, soft drinks, chips, snacks, fruit juice, peanut butter, soups, ice cream, jams, jellies, yogurt, and many breads have added sugars. Five Alive, for example, portrayed by its suppliers as "all natural" and featuring pictures of five different types of fruit on its label, comprises only 41% fruit juice, having high fructose corn syrup as its primary ingredient.

Concerns of vegetarians and vegans

The sugar refining industry often uses bone char ( calcinated animal bones) for decolorizing. This may concern some vegans and vegetarians; about a quarter of the sugar in the U.S. gets processed using bone char as a filter and the rest gets processed with activated carbon. As bone char does not get into the sugar, the relevant authorities consider sugar processed this way as parve/ kosher.

Vegetarians and vegans may also object to the impact that the burning of the cane fields (a common part of the harvesting practice) has on insects, rats, snakes, and other life residing in the fields.

Production

Table sugar (sucrose) comes from plant sources. Two important sugar crops predominate: sugarcane (Saccharum spp.) and sugar beets (Beta vulgaris), in which sugar can account for 12% to 20% of the plant's dry weight. Some minor commercial sugar crops include the date palm (Phoenix dactylifera), sorghum (Sorghum vulgare), and the sugar maple (Acer saccharum). In the financial year 2001/2002, worldwide production of sugar amounted to 134.1 million tonnes.

The first production of sugar from sugarcane took place in India. Alexander the Great's companions reported seeing "honey produced without the intervention of bees" and it remained exotic in Europe until the Arabs started cultivating it in Sicily and Spain. Only after the Crusades did it begin to rival honey as a sweetener in Europe. The Spanish began cultivating sugarcane in the West Indies in 1506 (and in Cuba in 1523). The Portuguese first cultivated sugarcane in Brazil in 1532.

Most cane sugar comes from countries with warm climates, such as Brazil, India, China, Thailand, Mexico and Australia, the top sugar-producing countries in the world. Brazil overshadows most countries, with roughly 30 million tonnes of cane sugar produced in 2006, while India produced 21 million, China 11 million, and Thailand and Mexico roughly 5 million each. Viewed by region, Asia predominates in cane sugar production, with large contributions from China, India and Thailand and other countries combining to account for 40% of global production in 2006. South America comes in second place with 32% of global production; Africa and Central America each produce 8% and Australia 5%. The United States, the Caribbean and Europe make up the remainder, with roughly 3% each.

Beet sugar comes from regions with cooler climates: northwest and eastern Europe, northern Japan, plus some areas in the United States (including California). In the northern hemisphere, the beet-growing season ends with the start of harvesting around September. Harvesting and processing continues until March in some cases. The availability of processing plant capacity, and the weather both influence the duration of harvesting and processing - the industry can lay up harvested beet until processed, but frost-damaged beet becomes effectively unprocessable.

The European Union (EU) has become the world's second-largest sugar exporter. The Common Agricultural Policy of the EU sets maximum quotas for members' production to match supply and demand, and a price. Europe exports excess production quota (approximately 5 million tonnes in 2003). Part of this, "quota" sugar, gets subsidised from industry levies, the remainder (approximately half) sells as "C quota" sugar at market prices without subsidy. These subsidies and a high import tariff make it difficult for other countries to export to the EU states, or to compete with the Europeans on world markets.

The United States sets high sugar prices to support its producers, with the effect that many former consumers of sugar have switched to corn syrup (beverage manufacturers) or moved out of the country (candymakers).

The cheap prices of glucose syrups produced from wheat and corn (maize) threaten the traditional sugar market. Used in combination with artificial sweeteners, they can allow drink manufacturers to produce very low-cost goods.

Cane

Since the 6th century BC cane sugar producers have crushed the harvested vegetable material from sugarcane in order to collect and filter the juice. They then treat the liquid (often with lime (calcium oxide)) to remove impurities and then neutralize it. Boiling the juice then allows the sediment to settle to the bottom for dredging out, while the scum rises to the surface for skimming off. In cooling, the liquid crystallizes, usually in the process of stirring, to produce sugar crystals. Centrifuges usually remove the uncrystallized syrup. The producers can then either sell the resultant sugar, as is, for use; or process it further to produce lighter grades. This processing may take place in another factory in another country. Sugar cane appears fourth in the list for agriculture in China.

Beet

Beet sugar producers slice the washed beets, then extract the sugar with hot water in a " diffuser". An alkaline solution (" milk of lime" and carbon dioxide from the lime kiln) then serves to precipitate impurities (see carbonatation). After filtration, evaporation concentrates the juice to a content of about 70% solids, and controlled crystallisation extracts the sugar. A centrifuge removes the sugar crystals from the liquid, which gets recycled in the crystalliser stages. When economic constraints prevent the removal of more sugar, the manufacturer discards the remaining liquid, now known as molasses.

Sieving the resultant white sugar produces different grades for selling.

Cane versus beet

Little perceptible difference exists between sugar produced from beet and that from cane. Chemical tests can distinguish the two, and some tests aim to detect fraudulent abuse of European Union subsidies or to aid in the detection of adulterated fruit juice.

The production of sugarcane needs approximately four times as much water as the production of sugar beet, therefore some countries that traditionally produced cane sugar (such as Egypt) have seen the building of new beet sugar factories recently. On the other hand, sugar cane tolerates hot climates better. Some sugar factories process both sugar cane and sugar beets and extend their processing period in that way.

The production of sugar results in residues which differ substantially depending on the raw materials used and on the place of production. While cooks often use cane molasses in food preparation, humans find molasses from sugar beet unpalatable, and it therefore ends up mostly as industrial fermentation feedstock (for example in alcohol distilleries), or as animal feed. Once dried, either type of molasses can serve as fuel for burning.

Culinary sugars

So-called raw sugars comprise yellow to brown sugars made by clarifying the source syrup by boiling and drying with heat, until it becomes a crystalline solid, with minimal chemical processing. Raw beet sugars result from the processing of sugar beet juice, but only as intermediates en route to white sugar. Types of raw sugar include demerara, muscovado, and turbinado. Mauritius and Malawi export significant quantities of such specialty sugars. Manufacturers sometimes prepare raw sugar as loaves rather than as a crystalline powder, by pouring sugar and molasses together into molds and allowing the mixture to dry. This results in sugar-cakes or loaves, called jaggery or gur in India, pingbian tang in China, and panela, panocha, pile, piloncillo and pão-de-açúcar in various parts of Latin America. In South America, truly raw sugar, unheated and made from sugarcane grown on farms, does not have a large market-share.

Mill white sugar, also called plantation white, crystal sugar, or superior sugar, consists of raw sugar where the production process does not remove colored impurities, but rather bleaches them white by exposure to sulfur dioxide. Though the most common form of sugar in sugarcane-growing areas, this product does not store or ship well; after a few weeks, its impurities tend to promote discoloration and clumping.

Blanco directo, a white sugar common in India and other south Asian countries, comes from precipitating many impurities out of the cane juice by using phosphatation — a treatment with phosphoric acid and calcium hydroxide similar to the carbonatation technique used in beet sugar refining. In terms of sucrose purity, blanco directo is more pure than mill white, but less pure than white refined sugar.

White refined sugar has become the most common form of sugar in North America as well as in Europe. Refined sugar can be made by dissolving raw sugar and purifying it with a phosphoric acid method similar to that used for blanco directo, a carbonatation process involving calcium hydroxide and carbon dioxide, or by various filtration strategies. It is then further purified by filtration through a bed of activated carbon or bone char depending on where the processing takes place. Beet sugar refineries produce refined white sugar directly without an intermediate raw stage. White refined sugar is typically sold as granulated sugar, which has been dried to prevent clumping.

Granulated sugar comes in various crystal sizes — for home and industrial use — depending on the application:

- Coarse-grained sugars, such as sanding sugar (also called "pearl sugar", "decorating sugar", nibbed sugar or sugar nibs) adds "sparkle" and flavor for decorating to baked goods, candies, cookies/ biscuits and other desserts. The sparkling effect occurs because the sugar forms large crystals which reflect light. Sanding sugar, a large-crystal sugar, serves for making edible decorations. It has larger granules that sparkle when sprinkled on baked goods and candies and will not dissolve when subjected to heat.

- Normal granulated sugars for table use: typically they have a grain size about 0.5 mm across

- Finer grades result from selectively sieving the granulated sugar

- caster (or castor) (0.35 mm), commonly used in baking

- superfine sugar, also called baker's sugar, berry sugar, or bar sugar — favored for sweetening drinks or for preparing meringue

- Finest grades

- Powdered sugar, 10X sugar, confectioner's sugar (0.060 mm), or icing sugar (0.024 mm), produced by grinding sugar to a fine powder. The manufacturer may add a small amount of anticaking agent to prevent clumping — either cornstarch (1% to 3%) or tri- calcium phosphate.

Retailers also sell sugar cubes or lumps for convenient consumption of a standardised amount. Suppliers of sugarcubes make them by mixing sugar crystals with sugar syrup. Jakub Kryštof Rad invented sugarcubes in 1841.

Brown sugars come from the late stages of sugar refining, when sugar forms fine crystals with significant molasses content, or from coating white refined sugar with a cane molasses syrup. Their colour and taste become stronger with increasing molasses content, as do their moisture-retaining properties. Brown sugars also tend to harden if exposed to the atmosphere, although proper handling can reverse this.

The World Health Organisation and the Food and Agriculture Organization of the United Nations expert report (WHO Technical Report Series 916 Diet, Nutrition and the Prevention of Chronic Diseases) defines free sugars as all monosaccharides and disaccharides added to foods by the manufacturer, cook or consumer, plus sugars naturally present in honey, syrups and fruit juices. This includes all the sugars referred to above. The term distinguishes these forms from all other culinary sugars added in their natural form with no refining at all.

Natural sugars comprise all completely unrefined sugars: effectively all sugars not defined as free sugars. The WHO Technical Report Series 916 Diet, Nutrition and the Prevention of Chronic Diseases approves only natural sugars as carbohydrates for unrestricted consumption. Natural sugars come in fruit, grains and vegetables in their natural or cooked form.

Chemistry

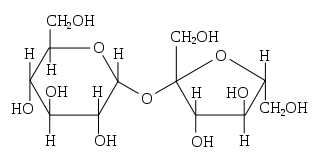

Biochemists regard sugars as relatively simple carbohydrates. Sugars include monosaccharides, disaccharides, trisaccharides and the oligosaccharides - containing 1, 2, 3, and 4 or more monosaccharide units respectively. Sugars contain either aldehyde groups (-CHO) or ketone groups (C=O), where there are carbon-oxygen double bonds, making the sugars reactive. Most simple sugars (monosaccharides) conform to (CH2O)n where n is between 3 and 7. A notable exception, deoxyribose, as its name suggests, has a "missing" oxygen atom. All saccharides with more than one ring in their structure result from two or more monosaccharides joined by glycosidic bonds with the resultant loss of a molecule of water (H2O) per bond.

As well as using classifications based on their reactive group, chemists may also subdivide sugars according to the number of carbons they contain. Derivatives of trioses (C3H6O3) are intermediates in glycolysis. Pentoses (5-carbon sugars) include ribose and deoxyribose, which form part of nucleic acids. Ribose also forms a component of several chemicals that have importance in the metabolic process, including NADH and ATP. Hexoses (6-carbon sugars) include glucose, a universal substrate for the production of energy in the form of ATP. Through photosynthesis plants produce glucose, which has the formula C6H12O6, and then convert it for storage as an energy reserve in the form of other carbohydrates such as starch, or (as in cane and beet) as sucrose (table sugar). Sucrose has the chemical formula C12H22O11.

Many pentoses and hexoses can form ring structures. In these closed-chain forms, the aldehyde or ketone group remains unfree, so many of the reactions typical of these groups cannot occur. Glucose in solution exists mostly in the ring form at equilibrium, with less than 0.1% of the molecules in the open-chain form.

Monosaccharides in a closed-chain form can form glycosidic bonds with other monosaccharides, creating disaccharides (such as sucrose) and polysaccharides (such as starch). Enzymes must hydrolyse or otherwise break these glycosidic bonds before such compounds become metabolised. After digestion and absorption. the principal monosaccharides present in the blood and internal tissues include glucose, fructose, and galactose.

The prefix "glyco-" indicates the presence of a sugar in an otherwise non-carbohydrate substance. Note for example glycoproteins, proteins connected to one or more sugars.

Monosaccharides include fructose, glucose, galactose and mannose. Disaccharides occur most commonly as sucrose (cane or beet sugar - made from one glucose and one fructose), lactose (milk sugar - made from one glucose and one galactose) and maltose (made of two glucoses). These disaccharides have the formula C12H22O11.

Hydrolysis can convert sucrose into a syrup of fructose and glucose, producing invert sugar. This resulting syrup, sweeter than the original sucrose, has uses in making confections because it does not crystallize as easily and thus produces a smoother finished product.

If combined with fine ash, sugar will burn with a blue flame.

Measuring sugar

See also International Commission for Uniform Methods of Sugar Analysis

Dissolved sugar content

Scientists and the sugar industry use degrees Brix (symbol °Bx), introduced by Antoine Brix, as units of measurement of the mass ratio of dissolved substance to water in a liquid. A 25 °Bx sucrose solution has 25 grams of sucrose per 100 grams of liquid; or, to put it another way, 25 grams of sucrose sugar and 75 grams of water exist in the 100 grams of solution.

An infrared Brix sensor measures the vibrational frequency of the sugar molecules, giving a Brix degrees measurement. This does not equate to Brix degrees from a density or refractive index measurement because it will specifically measure dissolved sugar concentration instead of all dissolved solids. When using a refractometer, one should report the result as "refractometric dried substance" (RDS). One might speak of a liquid as having 20 °Bx RDS. This refers to a measure of percent by weight of total dried solids and, although not technically the same as Brix degrees determined through an infrared method, renders an accurate measurement of sucrose content, since sucrose in fact forms the majority of dried solids. The advent of in-line infrared Brix measurement sensors has made measuring the amount of dissolved sugar in products economical using a direct measurement.

Purity

Technicians usually measure the purity (sucrose content) of sugar by polarimetry — the measurement of the rotation of plane-polarized light by a solution of sugar.

Baking weight/mass volume relationship

Different culinary sugars have different densities due to differences in particle size and inclusion of moisture.

The Domino Sugar Company has established the following volume to weight conversions:

- Brown sugar 1 cup = 195g = 6.88 oz

- Granular sugar 1 cup = 200g = 7.06 oz

- Powdered sugar 1 cup = 120g = 4.23 oz

Trade and economics

Historically one of the most widely-traded commodities in the world, sugar accounts for around 2% of the global dry cargo market. International sugar prices show great volatility, ranging from around 3 to over 60 cents per pound in the past 50 years. Of the world's 180-odd countries, around 100 produce sugar from beet or cane, a few more refine raw sugar to produce white sugar, and all countries consume sugar. Consumption of sugar ranges from around 3 kilograms per person per annum in Ethiopia to around 40 kg/person/yr in Belgium. Consumption per capita rises with income per capita until it reaches a plateau of around 35kg per person per year in middle income countries.

Many countries subsidize sugar production heavily. The European Union, the United States, Japan and many developing countries subsidize domestic production and maintain high tariffs on imports. Sugar prices in these countries have often exceeded prices on the international market by up to three times; today, with world market sugar futures prices currently strong, such prices typically exceed world prices by two times.

Within international trade bodies, especially in the World Trade Organization, the " G20" countries led by Brazil have long argued that because these sugar markets essentially exclude cane sugar imports, the G20 sugar producers receive lower prices than they would under free trade. While both the European Union and United States maintain trade agreements whereby certain developing and less developed country (LDCs) can sell certain quantities of sugar into their markets, free of the usual import tariffs, countries outside these preferred trade régimes have complained that these arrangements violate the " most favoured nation" principle of international trade. This has led to numerous tariffs and levies in the past.

In 2004, the WTO sided with a group of cane sugar exporting nations (led by Brazil and Australia) and ruled the EU sugar-régime and the accompanying ACP-EU Sugar Protocol (whereby a group of African, Caribbean, and Pacific countries receive preferential access to the European sugar market) illegal. In response to this and to other rulings of the WTO, and owing to internal pressures on the EU sugar-régime, the European Commission proposed on 22 June 2005 a radical reform of the EU sugar-régime, cutting prices by 39% and eliminating all EU sugar exports. The African, Caribbean, Pacific and least developed country sugar exporters reacted with dismay to the EU sugar proposals,. On 25 November 2005 the Council of the EU agreed to cut EU sugar prices by 36% as from 2009. In 2007 it seemed that the U.S. Sugar Program could become the next target for reform. However, some commentators expected heavy lobbying from the U.S. sugar industry, which donated $2.7 million to US House and US Senate incumbents in the 2006 US election, more than any other group of US food-growers. Especially prominent lobbyists include The Fanjul Brothers, so-called "sugar barons" who made the single largest individual contributions of soft money to both the Democratic and Republican parties in the political system of the United States of America.

Small quantities of sugar, especially specialty grades of sugar, reach the market as ' fair trade' commodities; the fair trade system produces and sells these products with the understanding that a larger-than-usual fraction of the revenue will support small farmers in the developing world. However, whilst the Fairtrade Foundation offers a premium of USD 60.00 per tonne to small farmers for sugar branded as "Fairtrade", government schemes such the U.S. Sugar Program and the ACP Sugar Protocol offer premiums of around USD 400.00 per tonne above world market prices. However, the EU announced on 14 September 2007 that it had offered "to eliminate all duties and quotas on the import of sugar into the EU".

The Sugar Association has launched a campaign to promote sugar over artificial substitutes. The Association now aggressively challenges many common beliefs regarding negative side effects of sugar consumption. The campaign aired a high-profile television commercial during the 2007 Prime Time Emmy Awards on FOX Television. The Sugar Association uses the trademark tagline "Sugar: sweet by nature."